Customized FPC cable

1、 Overview of "Customized FPC Cable"

With the continuous development of electronic products, more and more manufacturers are using FPC cables. FPC cable is a flexible interconnecting cable formed by using a flexible substrate as a carrier, laying conductive copper foil on the surface, and undergoing specific processing. It has the characteristics of flexibility and portability, which can meet the needs of high-speed transmission and space saving. However, different application scenarios have different requirements, so customizing fpc cables has become a necessity for many customers. This article aims to provide readers with a deep analysis of the knowledge related to customized FPC cables.

2、 Classification of fpc cables

FPC cables can be divided into various types based on their purpose and design structure, mainly including single-layer, double-layer, multi-layer, and so on. They also differ in form and component structure, and their corresponding application scenarios are also different.

The most common is a single-layer fpc cable. This type of cable only contains one layer of copper foil and one layer of substrate, and is longitudinally insulated through thin film insulation agent. Its lightweight and soft characteristics determine that it is usually suitable for circuit boards that are flexible in connection and require stretching and deformation adjustment (such as flexible circuit boards). However, the wire system of single-layer FPC flexible cables has drawbacks, and the interference between each coil is easily limited, which cannot meet the application requirements of high-performance processors. Therefore, in some applications that require high-performance processing chips, multi-layer fpc cables will be more suitable for use. The multi-layer structure of FPC cables not only has single-layer flexibility and lightweight volume, but also has good electromagnetic shielding performance and high signal propagation performance.

3、 The demand for customized FPC cables

The application range of modern electronic devices is becoming increasingly widespread, so the requirements for transmission lines (FPCs) are also increasing, directly affecting the quality and performance of products. Customizing according to customer needs is one of the most common requirements. Compared to standard products, customized products have higher cost-effectiveness, saving costs for customers while maintaining quality.

Due to the flexibility and designability of customization, as well as being suitable for special application needs, customized FPC flexible cables are used in some unique application scenarios, such as in compact space design, which require FPC cables to have the characteristics to work normally in specific environments. At the same time, in a large-scale production environment, customized FPC cables can also provide shorter cycle times to meet customer needs and minimize the company's inventory freeze capital.

4、 The manufacturing process of customized FPC cables

The manufacturing process of customized FPC cables mainly includes the following steps:

(1) Substrate selection and cutting

In this step, it is necessary to select suitable substrates and cut and plane edges according to standard dimensions. Choosing standardized substrates can maximize production efficiency and quality.

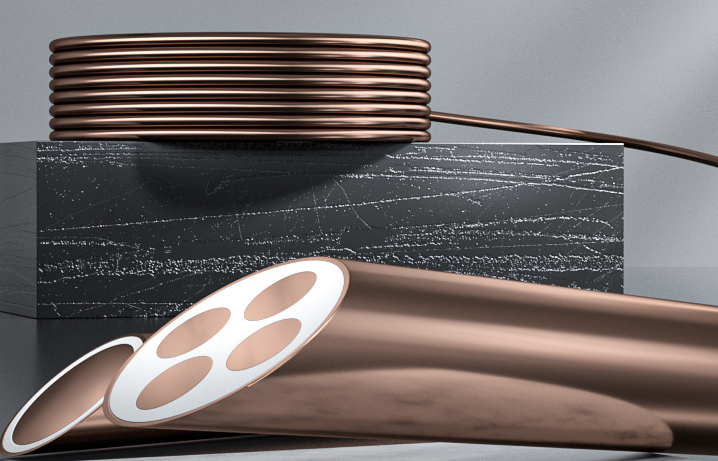

(2) Metallurgy of conductive copper foil

It is necessary to pre determine the applicable copper foil metallurgical method and select the corresponding metallurgical process according to the requirements, and bond the conductive copper foil onto the substrate separately.

(3) Copper foil pressing

The copper foil layer of the FPC cable will pass through high voltage and be pressed under high-precision temperature and pressure control. This process can form and bond conductive copper foil with the substrate, thereby forming strong adhesion and conductivity.

(4) Chemical and Mechanical Processing

This process mainly involves selecting appropriate chemical and mechanical processing methods to process and treat the FPC cable. Including perforation, graphic and exquisite laser cutting, and ultimately achieving customized design for FPC cables.

(5) Installation and Testing

The installation of FPC cables requires strict inspection and testing by the manufacturer to ensure the quality of the final product. The testing includes conducting tests, resistance tests, and other testing methods to ensure that the product meets customer requirements and regulations.

5、 Conclusion

FPC cables are one of the indispensable components in high-performance and functional electronic devices, which have a direct impact on the application range and product quality. With the increasing number of demanding application scenarios, customers' demand for customized fpc cables will gradually increase. This article explores the relevant knowledge of customized fpc cables from three perspectives: classification of fpc cables, requirements for customized fpc cables, and analysis of the manufacturing process. It summarizes that the demand for customized fpc cables will continue to increase in the future, and improving the production efficiency and quality of fpc cables is the current operational goal.